-

Applications & Solutions公司产品主要运用于核电、石油、石化、化工、电力、汽车、造船、化肥、医药、造纸、制糖、机械制造等工业装备行业。

Applications & Solutions公司产品主要运用于核电、石油、石化、化工、电力、汽车、造船、化肥、医药、造纸、制糖、机械制造等工业装备行业。 -

Products Diversity我们的产品:黑色金属矿原料(镍矿、镍铁、铬铁、锰铁、硅铁等)、无缝管、焊管、中厚板、板卷、棒材、 盘条、盘丝、管件、法兰、铸件等。

Products Diversity我们的产品:黑色金属矿原料(镍矿、镍铁、铬铁、锰铁、硅铁等)、无缝管、焊管、中厚板、板卷、棒材、 盘条、盘丝、管件、法兰、铸件等。 -

-

Production Videos公司产品主要运用于核电、石油、石化、化工、电力、汽车、造船、化肥、医药、造纸、制糖、机械制造等工业装备行业。

Production Videos公司产品主要运用于核电、石油、石化、化工、电力、汽车、造船、化肥、医药、造纸、制糖、机械制造等工业装备行业。 -

About Us上海鑫鑫荣特钢材料有限公司于2012年通过德国莱茵检测认证服务有限公司TUV Rheinland 的ISO9001国际质量体系认证,现正和英国英国船级社子公司劳氏质量认证公司 LRQA (Lloyd's Register Quality Assurance)申请认证通过ISO9001质量体系、ISO14001国际环境管理体系和ISO45001职业健康管理体系国际认证。

About Us上海鑫鑫荣特钢材料有限公司于2012年通过德国莱茵检测认证服务有限公司TUV Rheinland 的ISO9001国际质量体系认证,现正和英国英国船级社子公司劳氏质量认证公司 LRQA (Lloyd's Register Quality Assurance)申请认证通过ISO9001质量体系、ISO14001国际环境管理体系和ISO45001职业健康管理体系国际认证。

U Tubes

U Tubes

+

1. General specifications:

2. Tube Sizes for heat exchangers and condensers-Imperial sizes BWG:

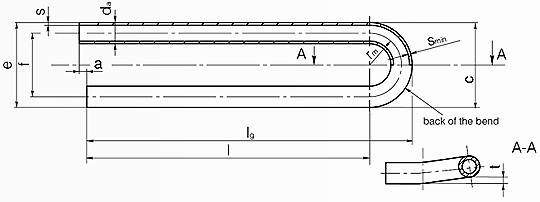

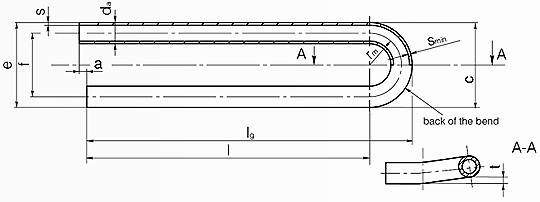

3. U-bend definitions and description:

a.....difference in length of legs

c.....distance between points of tangency

da....nominal outside diameter of tube

e.....distance between legs measured on OD

f......distance between legs

l......leg length

lg.....developed length

rm....nominal bend radius

S.....nominal wall thickness

Smin..minimum wall thickness at the back of the bend

t......deviation from plane of the bend

S0....minimum wall thickness defined by specification

4. Heat treatment:

If specified, we are equipped to carry out heat treatment of bends plus min. 150 mm of leg.

· Furnace is computer controlled and all data is recorded.

· We use an argon protective atmosphere inside the tubes.

· We can provide all types of annealing: Solution; Stress relieving; Stabilization.

5. Technical parameters:

OD 12.7-38 mm.

Bending radii from 1.5xOD up to 1250 mm. Minimum bending radii for OD′s over 28 mm after agreement.

Leg length min. 1,000 mm.

Leg length max. 12,000 mm.

Heat treatment for radii up to 1,000 mm.

6. Technical standards for bending:

Other specifications or special requirements available upon request. Copies of common standard specifications are available on request.

7. Hydrotesting:

· After heat treatment all U-tubes are hydrotested.

· Minimum holding time at the required pressure is 5 sec.

· All tubes are dried and carefully cleaned after testing.

8. Measuring, cutting, deburring, cleaning:

· U-bends are measured exactly in accordance with relevant standards, or to customer’s specification.

· All tubes are cut to the specified leg lengths, ends are deburred and the tubes are internally cleaned with air.

· Before packing, both ends are capped with plastic caps.

9. Packing:

· In strong, open or closed, wooden boxes depending on destination - max. 8,000 kg.

· Ends of tubes protected by plastic caps.

· Vertical separators for each radius.

· Chloride free plastic separators between each row, every 2 meters.

· Each bundle is covered with plastic.

· Customers can provide a packing drawing.

· Packing lists, covered with plastic, are placed on each wooden box for easy identification of order details – including exact list of radii and lengths inside.

| Standards: | ASTM A 213, ASME SA 213, ASTM A 249, ASME SA 249, ASTM A 688, ASME SA 688, ASTM A 789, ASME SA 789, ASTM B 163, ASME SB 163, ASTM B 167, ASME SB 167, ASTM B 668, ASME SB 668 |

| Materials: | 304/L/H, 316/L/TI, 317/L, 321/H, 347/H, 310S, S31500, S31803,S32205, S32750, S32760, S32001, S32304, N06600, N06625,N08800, N08810, N08811, N08825, N08904, N04400,TI GR.1/GR.2 |

2. Tube Sizes for heat exchangers and condensers-Imperial sizes BWG:

| Outside Diameter | BWG | |||||||

| 22 | 20 | 18 | 16 | 14 | 12 | 10 | ||

| Wall Thickcess mm | ||||||||

| 0.71 | 0.89 | 1.24 | 1.65 | 2.11 | 2.77 | 3.40 | ||

| mm | Inches | Weight Kg/m | ||||||

| 12.70 | 1/2 | 0.214 | 0.263 | 0.356 | 0.457 | - | - | - |

| 15.88 | 5/8 | 0.271 | 0.334 | 0.455 | 0.588 | - | - | - |

| 19.05 | 3/4 | 0.327 | 0.405 | 0.553 | 0.729 | 0.895 | - | - |

| 25.40 | 1 | 0.440 | 0.546 | 0.750 | 0.981 | 1.234 | 1.574 | - |

| 31.75 | 11/4 | 0.554 | 0.688 | 0.947 | 1.244 | 1.574 | 2.014 | - |

| 38.10 | 11/2 | 0.667 | 0.832 | 1.144 | 1.514 | 1.904 | 2.454 | - |

| 44.50 | 13/4 | - | - | 1.342 | 1.774 | 2.244 | 2.894 | 3.50 |

| 50.80 | 2 | - | - | 1.549 | 2.034 | 2.574 | 3.334 | 4.03 |

3. U-bend definitions and description:

a.....difference in length of legs

c.....distance between points of tangency

da....nominal outside diameter of tube

e.....distance between legs measured on OD

f......distance between legs

l......leg length

lg.....developed length

rm....nominal bend radius

S.....nominal wall thickness

Smin..minimum wall thickness at the back of the bend

t......deviation from plane of the bend

S0....minimum wall thickness defined by specification

4. Heat treatment:

If specified, we are equipped to carry out heat treatment of bends plus min. 150 mm of leg.

· Furnace is computer controlled and all data is recorded.

· We use an argon protective atmosphere inside the tubes.

· We can provide all types of annealing: Solution; Stress relieving; Stabilization.

5. Technical parameters:

OD 12.7-38 mm.

Bending radii from 1.5xOD up to 1250 mm. Minimum bending radii for OD′s over 28 mm after agreement.

Leg length min. 1,000 mm.

Leg length max. 12,000 mm.

Heat treatment for radii up to 1,000 mm.

6. Technical standards for bending:

Other specifications or special requirements available upon request. Copies of common standard specifications are available on request.

7. Hydrotesting:

· After heat treatment all U-tubes are hydrotested.

· Minimum holding time at the required pressure is 5 sec.

· All tubes are dried and carefully cleaned after testing.

8. Measuring, cutting, deburring, cleaning:

· U-bends are measured exactly in accordance with relevant standards, or to customer’s specification.

· All tubes are cut to the specified leg lengths, ends are deburred and the tubes are internally cleaned with air.

· Before packing, both ends are capped with plastic caps.

9. Packing:

· In strong, open or closed, wooden boxes depending on destination - max. 8,000 kg.

· Ends of tubes protected by plastic caps.

· Vertical separators for each radius.

· Chloride free plastic separators between each row, every 2 meters.

· Each bundle is covered with plastic.

· Customers can provide a packing drawing.

· Packing lists, covered with plastic, are placed on each wooden box for easy identification of order details – including exact list of radii and lengths inside.

Tags: